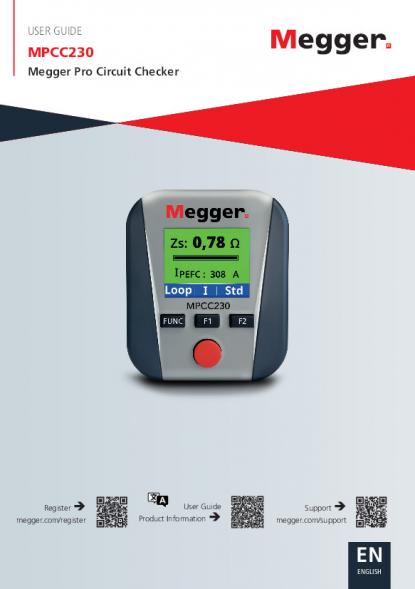

ENENGLISHUSER GUIDEMPCC230Megger Pro Circuit CheckerRegister megger.com/registerUser Guide Product Information Support megger.com/support

This document is copyright of:Megger Limited, Archcliffe Road, Dover, Kent CT17 9EN. ENGLAND T +44 (0)1304 502101 F +44 (0)1304 207342 www.megger.comMegger Limited reserves the right to alter the specification of its products from time to time without notice. Although every effort is made to ensure the accuracy of the information contained within this document it is not warranted or represented by Megger Limited to be a complete and up - to - date description.For Patent information about this instrument refer to the following web site: megger.com/patentswww.megger.comMPCC2302

Declaration of ConformityHereby, Megger Instruments Limited declares that radio equipment manufactured by Megger Instruments Limited described in this user guide is in compliance with Directive 2014/53/EU. Other equipment manufactured by Megger Instruments Limited described in this user guide is in compliance with Directives 2014/30/EU and 2014/35/EU where they apply.The full text of Megger Instruments EU declarations of conformity are available at the following internet address: megger.com/eu-dofc This manual supersedes all previous issues of this manual. Please ensure that you are using the most recent issue of this document. Destroy any copies that are of an older issue.www.megger.comMPCC2303

www.megger.comMPCC2304 Contents1. Introduction 61.1 Company web site 62. Safety Warnings and Standards 72.1 Warnings, Cautions and Notes 72.2 Safety warnings 72.2.1 Installation category definitions: 82.3 Safety, Hazard and Warning symbols on the instrument 83. Instrument Overview 93.1 Instrument layout 94. Operation 104.1 Volt and socket test 104.1.1 Operation 104.2 RCD (residual current device) 114.2.1 Test mode: 114.2.2 RCD x1/2, x1, x5 and Auto Operation 114.2.3 RCD AUTO function 114.3 LOOP 134.3.1 Test modes: 134.3.2 LOOP test operation 134.4 HAR voltage harmonics 134.4.1 Test mode: 134.4.2 Harmonics function 134.5 MEM Memory / REPORT 144.5.1 Operation 144.5.2 Report create 144.5.3 MEMORY 155. Maintenance 165.1 General maintenance 165.2 Cleaning 166. Specifications 17

www.megger.comMPCC2305 7. Calibration, Repair and Warranty 197.1 Calibration, Service and Spare Parts 207.2 Approved Repair Companies 207.3 Return procedure 208. Decommissioning 218.1 WEEE Directive 218.2 Battery disposal 219. Worldwide Sales Offices 22

www.megger.comMPCC2306Introduction1. IntroductionThe Megger MPCC230 is a compact socket tester and circuit checker, in one unit. It is designed to allow the user to test the correct wiring polarity of a socket as well as check the circuit earth loop and protective RCD during routine maintenance or inspection.In addition, the condition of the mains voltage supply can be measured, along with frequency, and an indication of the total harmonic distortion displayed.The advanced features make the MPC230 an invaluable circuit checker. Incorrect polarity is shown in detail and - because of the TFT colour display - indicated clearly by a red test bar.With the ability to measure earth loop impedance on RCD protected circuits, as well as calculate the prospective earth fault current and show the touch voltage value, it aids routine inspection of an installation.An auto-RCD test will confirm the operation of the protective device at measure the contact voltage value.In addition, the MPCC230 will not only provide the TRMS supply voltage, but also indicate the total harmonic distortion measured and allow the user to identity which harmonics are present.With a memory function capable of storing up to 64 loop impedance or RCD test values, these can be downloaded using the free app for simple report generation.1.1 Company web siteOccasionally an information bulletin may be issued via the Megger web site. This may concern new accessories, new usage or user instructions or a software update. Please occasionally check on the Megger web site for anything applicable to your Megger instruments.www.megger.com

www.megger.comMPCC2307Safety Warnings and Standards2. Safety Warnings and StandardsThese safety warnings must be read and understood before the instrument is used. Retain for future reference.2.1 Warnings, Cautions and NotesThis user guide follows internationally recognised definitions.DescriptionWARNING : Indicates a potentially dangerous situation which, if ignored, could lead to death, serious injury or health problems. CAUTION : Indicates a situation which could lead to damage of the equipment or environmentNOTE : Indicates important instructions to be followed to perform the relevant process safely and efficiently.2.2 Safety warnings Understand and follow the operating instructions carefully. No user serviceable parts inside.This product is manufactured following IEC/EN61010-1, guidelines for safety installation testers. Follow this user manual to avoid damaging the instrument: Do not use in high humidity or wet environment. Do not use in an explosive atmosphere. The maximum input voltage is 250 V. Connecting to higher voltages will cause permanent damage to the instrument and may give rise to the potential of electric shock. Extreme care must be taken when measuring above 50 V. The circuit checker must not be used if any part of it is damaged. Check for correct operation by testing a known voltage before and after use. Do not use it if misleading results are obtained. Warnings and precautions must be read and understood before the circuit checker is used. They must be observed during the operation of this circuit checker. Personal protective equipment should be used if there are ACCESSIBLE HAZARDOUS LIVE PARTS in the installation where measurement is to be carried out. Do not use on or around uninsulated hazardous live conductors where a potential to cause electric shock, electrical burns or arc flash exists.

www.megger.comMPCC2308Safety Warnings and Standards2.2.1 Installation category definitions:CAT IV - Measurement category IV: Equipment connected between the origin of the low-voltage mains supply and distribution panel.CAT III -Measurement category III: Equipment connected between the distribution panel and electrical outlets.CAT II - Measurement category II: Equipment connected between the electrical outlets and user’s equipment.Measurement equipment may be safely connected to circuits at the marked rating or lower. The connection rating is that of the lowest rated component in the measurement circuit.2.3 Safety, Hazard and Warning symbols on the instrumentThis paragraph details the various safety and hazard icons on the instrument’s outer case.Icon DescriptionWarning: High Voltage, risk of electric shockCaution: Refer to user guideDouble/reinforced insulation throughoutUK conformity. This equipment complies with current UK legislationEU conformity. Equipment complies with current EU directivesConforms to relevant Australian Safety and EMC standards>250 VProhibited for use on electrical systems above 250 VDo not dispose of in the normal waste stream

www.megger.comMPCC2309Instrument Overview3. Instrument Overview3.1 Instrument layout6513247ItemDescriptionDisplay1 TEST buttonStarts a test or selects memory download bar code2 Function button to select the measurement mode.Socket Test / VOLT - RCD - LOOP - Harmonics / Memory.3 Sub-function navigationCycle through displayed features or memory values4Display TFT 1,77”5Anti-scratch glass6UK plug7EU plug

www.megger.comMPCC23010Operation 4. Operation The MCPP230 will execute the following tests:1. Socket polarity 2. TRMS voltage and frequency3. Protective device (RCD/RCBO) type A, AC and F4. No-trip earth loop impedance 5. Prospective earth fault current and touch voltage6. Voltage harmonics up to 50th7. THD% (Total harmonics distortion)Tests are selected by pressing the FUNC button. Sub-function features can be selected through the F1 and F2 buttons, for example for selecting the RCD type or displaying different harmonics. The instrument is powered through the line input, but with the supercap technology, the display will remain visible. Fully charged, the supercap will allow ~45 seconds of use after switch off from the line. This allows the user to remove the unit and read the displayed result. This is useful, should the socket be mounted in a hard to access location.4.1 Volt and socket testThis feature measures Voltage between phase and neutral and tests the socket wiring and polarity in accordance to local requirement.

www.megger.comMPCC23011Operation 4.1.1 Operation1. Plug the instruments into the socket and press the FUNC button to select the Voltage function. 2. Voltage between Phase and Neutral will be shown on the display. Pressing the F2 button will cycle to the measured frequency and the units firmware and serial number. Pressing F1 cycles back to voltage. 2.1. If the socket wiring is correct and the measured earth touch voltage is less than 50 V, a green bar indicates all parameters are correct.2.2. If an error occurs due to incorrect wiring or a high voltage detected on the earth, the bar will turn red and an audible alarm will sound. The unit will display the failed parameter on the screen (examples in Fig 2 and 3). Fig. 1 Fig. 2 Fig. 3 Code displayedWiring error (bar is Red and sound alarm) SolutionL-NPhase - Neutral Reverse Correct the socket wiringL-NPhase - Earth Reverse Correct the socket wiringL-PEOpen Neutral Connect Neutral wireNO PENo Earth Check Earth connectionVT >50VTouch Voltage >50VDangerous Voltage on Earth4.2 RCD (residual current device)This feature carries out an RCD test, with both measured tripping times and contact voltage results displayed.4.2.1 Test mode: x1/2 IΔn Test with 15 mA x1 IΔn Test with 30 mA x5 IΔn Test with 150 mA AUTO Test sequence x1/2 0° and 180° x1 0° and 180° x5 0° and 180°

www.megger.comMPCC23012Operation 4.2.2 RCD x1/2, x1, x5 and Auto Operation1. Plug the instruments into the socket and press the FUNC button to select the RCD function. 2. Press the F1 button to select the type of RCD and F2 button to select the current (x1/2, x1, x5 or Auto).3. Press and hold the RED test button for 3 seconds to start the test.4. The trip time and contact voltage results are shown on the display.4.1. A green bar indicates the trip time and contact voltage are within specification (Fig 4).4.2. If the trip time exceeds the predefined pass levels (refer to table in Auto RCD section below) or the contact voltage >50 V, a red bar is shown, indicating a fail. Fig. 4 Fig. 54.2.3 RCD AUTO function1. Plug the instrument in the socket and press FUNC button to select the RCD function. 2. Press the F1 button to select the type of RCD and F2 button to select AUTO. 3. Press the RED test button to start the test.4. The instruments will execute all tests in sequence, reset the RCD between each step. AUTO mode consist of 6 test in the following sequence: STEP 1IΔn x1/2 0°OK IF >1000 msSTEP 2IΔn x1/2 180°OK IF >1000 msSTEP 3IΔn x1 0°OK IF <300 msSTEP 4IΔn x1 180°OK IF <300 msSTEP 5IΔn x5 0°OK IF <40 msSTEP 6IΔn x5 180°OK IF <40 ms 0 ̊180 ̊msmssx5x1x½ 787836RCDAAuto38>1>1 Fig 6 0 ̊180 ̊msmssx5x1x½ 7878>1>1RCDAAuto>40 fig 75. RCD Tripping Time is shown on the display in ms for every STEP.5.1. Passed trip time results are displayed in GREEN (Fig 6).5.2. Failed trip times will be displayed in red (Fig 7) and the test will be stopped.

www.megger.comMPCC23013Operation 4.3 LOOPLoop test measures the impedance between Phase and Earth/Ground without a RCD trip.CAUTION : The MPCC230 uses a low current no-trip loop test method. However, this DOES NOT guarantee an RCD will not trip. Accumulative or highly sensitive RCDs or RCBOs may still trip, so care should be taken to ensure that a loss of supply will not cause a hazardous situation to arise.4.3.1 Test modes: V Measures Impedance Zs (Z L-Pe) (Ω) and Touch Voltage (V) (Fig.8) I Measures Impedance Zs (Z L-Pe) (Ω) and IPEFC Prospective Earth Fault Current (Fig.9) Std Test with 15 mA nominal current Low Test with 6 mA. Use this setup if during the test the RCD trip due to the presence of leakage current in the electric system under test.4.3.2 LOOP test operation1. Plug the instruments into the socket and press the FUNC button to select the LOOP function. 2. Press the F1 button to select V or I and F2 button to select TEST STD or LOW. 3. Press and hold the RED test button for 3 seconds to start the test. fig 8 fig 9WARNING : During the LOOP measurement, if the SUPERCAP is not fully charged, the display may switch off or decrease the intensity, however the measurement will be performed and shown at the end.4.4 HAR voltage harmonicsThis function checks the quality of the line voltage with regards to harmonics.4.4.1 Test mode: Fund Indicates the fundamental on the bar graph and displays the measured voltage and frequency. Total harmonic distorion (THD) is diaplayd as a percentage (Fig. 10). h2....h50 Shows the selected harmonic on the bar graph in red, along with the measured voltage and frequency. A harmonic distortion %, compared to the fundamental, is also displayed

www.megger.comMPCC23014Operation 4.4.2 Harmonics function1. Plug the instruments into the socket and press the FUNC button to select “HAR” function.2. Press the F1 and F2 buttons to select harmonics value required It is possible to disconnect the instrument from the power supply to read and analyse the measurements, until the SUPERCAP is discharged (approx 45 second when fully charged). fig 10 fig 114.5 MEM Memory / REPORTThe instrument automatically saves RCD and LOOP measurement to the internal memory.It is possible to store 64 consecutive measurement results. The results will be organized in chronological order with the last measurement saved in the first cell.4.5.1 Operation1. Plug the instruments into the socket and press the FUNC button to select MEM2. Press F1/F2 buttons to move through the saved data 3. Press both F1 and F2 to enter clear memory mode4. Press FUNC to clear memory or F2 to cancel4.5.2 Download the AppDownload the Megger Pro Circuit Checker App to a mobile device:

www.megger.comMPCC23015Operation 4.5.3 Report create5. In MEM mode, press the RED button to generate a results QR code on the display (Fig.12)6. With the Megger Pro Circuit Checker App running on your mobile device, select “Scan QR”. All saved measurements will be imported to the App and displayed in a simple report. This can then be exported in either PDF or csv format. All saved measurements will be included in a REPORT with the possibility of exporting in pdf or csv. fig 12 fig 134.5.4 MEMORY7. Fig. 13 shown the MEM results display. Column No is the internal memory cell number. FUNC shows the test type and Value indicates the measured result.8. For saved RCD measurements, a pass or fail value is shown as either GREEN or RED: 8.1. GREEN if the result has passed the test.8.2. RED if the result has not passed the test.

www.megger.comMPCC23016Maintenance5. MaintenanceNOTE : There are no user replaceable parts within this product.5.1 General maintenanceEnsure the unit is kept clean and dry after use.Store in protective case when not in use.5.2 CleaningDisconnect from mains power. Wipe the instrument with a clean cloth dampened with either water or isopropyl alcohol (IPA).

www.megger.comMPCC23017Specifications6. SpecificationsRCD TestTest voltage L-PE 190 to 250 V - Frequency 50 Hz ±5% RCD typeIΔnResolutionAccuracy IΔnAC, A, F, Time30 mA<0.1 IΔn 0.1 ms± (0.0% + 5% IΔn) ±2 ms + 2 dgt)Loop Impedance TestNo-trip earth loop impedance test voltage: 190 to 250 V (line-PE) Standard mode test current 15 mA Range (Ω)Resolution (Ω)Accuracy0.01 to 9.990.01± (5.0% + 8 dgt)10 to 99.90.1± (2.0% + 8 dgt)100 to 9991± (2.0% + 8 dgt)LOW mode test current 6 mA± (7.0% + 10 dgt)AC TRMS Voltage (Phase - Neutral)Allow crest factor: 1.5 Frequency : 42 to 69.0 Hz Range (V)Resolution (V)Accuracy120 to 2501± (1.0% + 3 dgt) FrequencyRange (Hz)Resolution (Hz)Accuracy42 to 690.1± (2.0% + 1 dgt) Voltage Harmonics1st to 50th (Harmonic voltages are zeroed if value <0.8 V) Range (V)Resolution (V)Accuracy0.8 to 2500.1± (3.0% + 5 dgt) Socket TestNo Earth - Phase neutral reverse - Phase earth reverse - Voltage N-Pe > 50 VINPUTMeasurement category: CAT II 250 V to groundMax Input: 250 VACGeneral reference standardsSafety of measuring instruments IEC/EN61010-1 IEC/EN61010-2-2017EMC IEC/EN61326-1Display and memoryFeatures TFT colour graphic LCDMemory safety section 64 resultsWorking environment conditionsReference temperature 5ºC to 23ºC

www.megger.comMPCC23018SpecificationsWorking temperature 5ºC to 40ºCRelative humidity <80%RHStorage temperature -10ºC to 60ºCStorage humidity <80%RHMechanical featuresDimensions 81.5 x 70 x 83 mmWeight 110 g

www.megger.comMPCC23019Calibration, Repair and Warranty7. Calibration, Repair and WarrantyMegger operate fully traceable calibration and repair facilities to make sure your instrument continues to provide the high standard of performance and workmanship that is expected. These facilities are complemented by a worldwide network of approved repair and calibration companies, which offer excellent in-service care for your Megger products.For service requirements for Megger instruments contact:Megger Limited Archcliffe Road Dover Kent CT17 9EN U.K. Tel: +44 (0) 1304 502 243 Fax: +44 (0) 1304 207 342ORMegger Valley Forge 400 Opportunity Way Phoenixville PA 19460 U.S.A. Tel: +1 610 676 8579 Fax: +1 610 676 8625If the protection of an instrument has been impaired it should not be used, but sent for repair by suitably trained and qualified personnel. The protection is likely to be impaired if, for example, the instrument shows visible damage, fails to perform the intended measurements, has been subjected to prolonged storage under unfavourable conditions, or has been exposed to severe transport stresses. New instruments are covered by a two year warranty from the date of purchase by the User, the second year being conditional on the free registration of the product on www.megger.com. You will need to log in, or first register and then login to register your product. The second year warranty covers faults, but not recalibration of the instrument which is only warranted for one year. Any unauthorised prior repair or adjustment will automatically invalidate the warranty. These products contain no User repairable parts and if defective should be returned to your supplier in original packaging or packed so that it is protected from damage during transit. Damage in transit is not covered by this warranty and replacement / repair is chargeable. Megger warrants this instrument to be free from defects in materials and workmanship, where the equipment is used for its proper purpose. The warranty is limited to making good this instrument (which shall be returned intact, carriage paid, and on examination shall disclose to their satisfaction to have been defective as claimed). Any unauthorised prior repair or adjustment will invalidate the warranty. Misuse of the instrument, from connection to excessive voltages, fitting incorrect fuses, or by other misuse is excluded from the warranty. The instrument calibration is warranted for one year. This Warranty does not affect your statutory rights under any applicable law in force, or your contractual rights arising from a sale and purchase contract for the product. You may assert your rights at your sole discretion.

www.megger.comMPCC23020Calibration, Repair and Warranty7.1 Calibration, Service and Spare Parts For service requirements for Megger Instruments contact Megger or your local distributor or authorised repair centre. Megger operates fully traceable calibration and repair facilities, to make sure your instrument continues to provide the high standard of performance and workmanship you expect. These facilities are complemented by a worldwide network of approved repair and calibration companies to offer excellent in-service care for your Megger products. See the last page of this User Guide for Megger contact details. To find your local Authorised Service Centre email Megger on ukrepairs@megger.com and give details of your location. 7.2 Approved Repair Companies A number of independent instrument repair companies have been approved to do repair work on most Megger instruments, complete with genuine Megger spare parts. Consult the Appointed Distributor / Agent about spare parts, repair facilities and advice. 7.3 Return procedureWARNING : Remove the battery cells before shipping this instrument.UK and USA Service Centres 1. When an instrument requires recalibration, or in the event of a repair being necessary, a Returns Authorisation (RA) number must first be obtained from one of the addresses shown above. The following information is to be provided to enable the Service Department to prepare in advance for receipt of your instrument and to provide the best possible service to you: Model (for example, MIT220). Serial number (Found on the VOLT screen by pressing F2 twice or shown on the rear of the instrument). Reason for return (for example, repair required)).2. Make a note of the RA number. A returns label can be emailed or faxed to you if required.3. Pack the instrument carefully to prevent damage in transit.4. Before the instrument is sent to Megger, freight paid, make sure that the returns label is attached or that the RA number is clearly marked on the outside of the package and on any correspondence. Copies of the original purchase invoice and packing note should be sent simultaneously by airmail to expedite clearance through customs. In the case of instruments which require repair outside the warranty period, an immediate quotation can be provided when obtaining the RA number.5. Track the progress online at www.megger.com.

www.megger.comMPCC23021Decommissioning8. Decommissioning8.1 WEEE DirectiveThe crossed out wheeled bin symbol placed on Megger products is a reminder not to dispose of the product at the end of its life with general waste.Megger is registered in the UK as a Producer of Electrical and Electronic Equipment. The Registration No is WEE/ HE0146QT.For further information about disposal of the product consult your local Megger company or distributor or visit your local Megger website.8.2 Battery disposalThe crossed out wheeled bin symbol placed on a battery is a reminder not to dispose of batteries with general waste when they reach the end of their usable life.For disposal of batteries in other parts of the EU contact your local Megger branch or distributor.Megger is registered in the UK as a producer of batteries (registration No.: BPRN00142).For further information see www.megger.com

www.megger.comMPCC23022Worldwide Sales Offices9. Worldwide Sales OfficesSales OfficeTelephoneEmailUKT. +44 (0)1 304 502101 E. UKsales@megger.comUSA – DallasT. +1 214 333 3201E. USsales@megger.comUSA – Valley ForgeT. +1 214 333 3201E. USsales@megger.comUSA – DallasT. +1 214 333 3201E. USsales@megger.comDEUTSCHLAND – AachenT. +49 (0) 241 91380 500E. info@megger.deSVERIGET. +46 08 510 195 00E. seinfo@megger.com中国T. +86 512 6556 7262 E. meggerchina@megger.com中国 - 香港T. +852 26189964E. meggerchina@megger.comČESKÁ REPUBLIKAT. +420 222 520 508E. info.cz@megger.comAmérica LatinaT. +1 214 330 3293E. csasales@megger.comESPAÑAT. +34 916 16 54 96E. info.es@megger.comSUOMIT. +358 08 510 195 00E. seinfo@megger.comLA FRANCET. +01 30 16 08 90E. infos@megger.comΕΛΛΑΔΑT. +49 (0) 9544 68 0E. sales@sebakmt.comMagyarországT. +36 1 214-2512E. info@megger.huITALIAT. +49 (0) 9544 68 0E. sales@sebakmt.com日本T. +44 (0)1 304 502101 E. UKsales@megger.com한국T. +1-800-723-2861E. sales@megger.comضايرلا ةيبرعلاT. +966 55 111 6836E. MEsales@megger.comنيرحبلا ةكلممT. +973 17440620E. MEsales@megger.comNEDERLANDT. +46 08 510 195 00E. seinfo@megger.comNORGET. +46 08 510 195 00E. seinfo@megger.comPOLSKAT. +48 22 2809 808E. info.pl@megger.comPORTUGALT. +34 916 16 54 96E. info.es@megger.comRomâniaT. +40 21 2309138E. info.ro@megger.comРОССИЯT. +7 495 2 34 91 61E. sebaso@sebaspectrum.ruSLOVENSKOT. +421 2 554 23 958 E. info.sk@megger.comTürkiyeT. +46 08 510 195 00E. seinfo@megger.com

www.megger.comMPCC23023

www.megger.comMPCC230_UG_en_V04The word ‘Megger’ is a registered trademark. Copyright © 2025Megger LimitedArchcliffe Road DoverKent CT17 9EN ENGLAND T. +44 (0)1 304 502101 F. +44 (0)1 304 207342Local Sales officeThis instrument is manufactured in the United Kingdom.The company reserves the right to change the specification or design without prior notice.Megger is a registered trademarkThe Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc and are used under licence.Megger LimitedDover, ENGLANDT. +44 (0)1 304 502101 E. uksales@megger.com Megger AB Danderyd, SWEDENT. +46 08 510 195 00 E. seinfo@megger.comMegger Valley ForgePhoenixville, PA USAT. +1 610 676 8500 E. USsales@megger.comMegger USA - DallasDallas, TX USAT. +1 214 333 3201 E. USsales@megger.comMegger USA - Fort CollinsFort Collins, CO USAT. +1 970 282 1200Manufacturing sitesMegger GmbHAachen, GERMANYT. +49 (0) 241 91380 500 E. info@megger.deMegger Germany GmbHBaunach, GERMANYT. +49 (0) 9544 68 - 0 E. baunach@megger.comMegger Germany GmbHRadeburg, GERMANYT. +49 (0) 35208 84-0 E. radeburg@megger.com