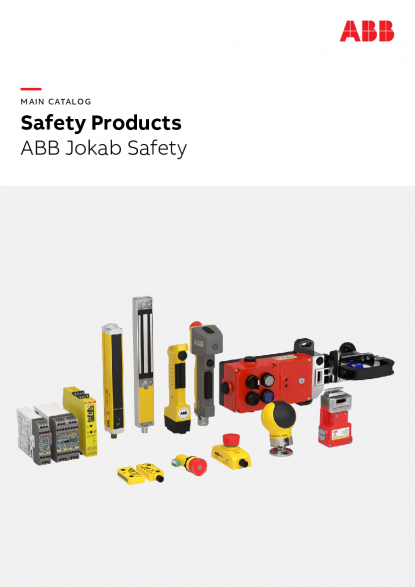

— MAIN CATALOG Safety ProductsABB Jokab Safety—ABB AB Jokab SafetyVarlabergsvägen 11SE-434 39 KungsbackaTel. +46 (0) 21-32 50 00www.abb.com/jokabsafetyCopyright© 2018 ABBAll rights reserved2TLC010001C0202

2637485INTRODUCTIONCONTROL DEVICESSAFETY CONTROLLERSEMERGENCY STOPS AND PILOT DEVICESOPTICAL SAFETY DEVICESPRESSURE SENSITIVE DEVICESSENSORS AND LOCKSCONTACTORS AND MOTOR STARTERS—Safety products catalogABB Jokab Safety1

1SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—Introduction1–2 Introduction 1–6 Standards and regulations 1INTRODUCTION1– 1

—Introduction Company overviewABB Jokab Safety has been helping machine builders to create production-friendly and safe work environments for operators since 1988.We develop products and solutions for machine safetyWe make it simple to build safety systems. Developing products and solutions for machine safety has been our business idea since the company Jokab Safety, now a part of ABB, was founded in Sweden in 1988. Many industries around the world have discovered how much easier it has become to build protection and safety systems with our components and guidance. Our extensive program of products, safety solutions and our long experience in ma-chine safety makes us a safe partner.Together we create a safe world!11– 2SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

Products and systemsWe deliver machine safety solutions for single machines or entire production lines. Our long experience of helping customers making solutions for demanding environments has made us experts in combining production demands with safety demands for production-friendly solutions.We market a wide range of safety products, which makes it easy to build safety systems. We develop these intelligent products continuously, in cooperation with our customers. Markets and industriesSolutions from ABB Jokab Safety can be found in all types of industries across the globe. But we pride ourselves in having products and solutions that are especially well suited for e.g.: - Robotics - Food and beverage - General machinery (OEM)—Introduction Company overviewOur experience of safety requirements and standardsDirectives and standards are very important to machine builders and safety component manufacturers. We represent Sweden in several international committees that develop standards, for e.g. industrial robots, safety distances and control system safety features. We work daily with the practical application of safety requirements in combination with production requirements. We are happy to share our knowledge of standards with our customers. You can use our experience for training and advice.1INTRODUCTION1– 3

Magne magnetic lockto keep doors and hatches locked during a processSmile emergency stop buttonto safely stop machinery in hazardous situationsSafeball control device for an ergonomic and safe two-hand controlJSHD4 three-position device for safe and ergonomic inspection and troubleshootingGKey safety lockfor safe locking of doorsMKey9 key switchfor safe locking of hatches and doorsInca emergency stop buttonfor compact panel mountingOrion light guardsfor a production friendly safety detectionEden sensorfor reliable non-contact monitoring of doors and hatchesPluto programmable safety controller,Vital safety controller and Sentry safety relaysfor flexible monitoring of safety devicesLineStrong pull wire emergency stop switch for easy access of emergency stop functionOperators and signalling devicesfor control and indicationMats, rails and bumpersto detect the presence of peopleContactors and electroniccompacts starters to control power and motors—Our range of safety products ABB is the only supplier that can deliver complete safety solutions (including output devices such as contactors and frequency converters) together with automation solutions such as robotics, motors, drives and PLCs.11– 4SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

Magne magnetic lockto keep doors and hatches locked during a processSmile emergency stop buttonto safely stop machinery in hazardous situationsSafeball control device for an ergonomic and safe two-hand controlJSHD4 three-position device for safe and ergonomic inspection and troubleshootingGKey safety lockfor safe locking of doorsMKey9 key switchfor safe locking of hatches and doorsInca emergency stop buttonfor compact panel mountingOrion light guardsfor a production friendly safety detectionEden sensorfor reliable non-contact monitoring of doors and hatchesPluto programmable safety controller,Vital safety controller and Sentry safety relaysfor flexible monitoring of safety devicesLineStrong pull wire emergency stop switch for easy access of emergency stop functionOperators and signalling devicesfor control and indicationMats, rails and bumpersto detect the presence of peopleContactors and electroniccompacts starters to control power and motors1INTRODUCTION1– 5

Harmonised standardsHarmonised standards give support on how to fulfill the requirements of the Machinery Directive. The relationship between the Machinery Directive and the harmonised stan-dards is illustrated by the diagram below.Within ISO (The International Organization for Standardiza-tion) work is also going on in order to harmonise the safety standards globally in parallel with the European standardi-sation work. ABB Jokab Safety takes an active part in the working groups both for the ISO and EN standards. Directives and standards are of great importance for manufacturers of machines and safety components. In the Europe-an Union, the EU Directives gives requirements for the minimum level of health and safety, and these are mandatory for manufacturers to fulfill. In every member country the Directives are implemented in national legislation.Machines which have been placed on the market since 2010, must comply with the new Machinery Directive2006/42/EC. Before that, the old Machinery Directive 98/37/EC was valid.Although the requirements in the Directives are specific for Europe, they also apply to machines that are imported to Eu-rope. And the Directives are supported by standards, of which many also are valid internationally. —European Directives and StandardsThe objectives of the Machinery Directive, 2006/42/EC, are to maintain, increase and equalise the safety level of machines within the members of the European Community. Based on this, the free movement of machines/products between the countries in this market can be achieved. The Machinery Directive is developed according to “The New Ap-proach” which is based on the following principles: –The directives give the basic health and safety require-ments, which are mandatory. –Detailed solutions and technical specifications are found in harmonised standards. –Standards are voluntary to apply, but products designed according to the harmonised standards will fulfill the basic safety requirements in the Machinery Directive.Giving basic concepts, principles for design, and general aspects that can be applied to all machineryB1: Standards on particular safety aspects (e.g. safety distances, surface temperature, noise)B2: Standards on safeguards (e.g. two-hand controls, interlocking devices, pressure sensi-tive devices, guards)Dealing with detailed safety requirements for a particular machine or group of machinesExamples of standardsA-standardsB1-standardsB2-standardsC-standardsEN ISO 1200EN ISO 13857EN 349EN ISO 13849-1 EN ISO 13855EN ISO 13850EN ISO 14119EN 60204-1EN ISO 10218-1EN 692EN 693The Machinery Directive2006/42/EC11– 6SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

The Machinery Directive, for machines and safety compo-nentsFrom 2006/42/EC1 § This Directive applies to the following products:a) machinery;b) interchangeable equipment;c) safety components;d) lifting accessories;e) chains, ropes and webbing;f) removable mechanical transmission devices;g) partly completed machinery.The Machinery Directive gives a detailed definition of a machine, which can be simplified as something that has linked parts that are moving, where the energy source is not human effort. Two or more machines that are put together into a production line is also regarded as one machine. CE-marking and Declaration of conformityMachines manufactured or placed on the market from december 29, 2009, shall be CE-marked and fulfil the requirements according to the European Machinery Direc-tive 2006/42/EC. This is also valid for old machines (manu-factured before 1 January 1995) if they are manufactured in a country outside the EEA and imported to be used in a country in the EEA (European Economic Area).For machines manufactured and/or released to the market between january 1, 1995, and december 28, 2009, the old Machinery Directive (98/37/EC) is valid.NOTE! Machines have to be accompanied by a Declaration of Con-formity (according to 2006/42/EC, Annex II 1.A) that states which directive and standards the machine fulfills. It also shows if the product has gone through EC Type Examina-tion. Safety components have to be accompanied with a Declara-tion of Conformity.Requirements for the use of machineryFor a machine to be safe it is not enough that the manufac-turer has been fulfilling all valid/necessary requirements. The user of the machine also has requirements to fulfill. For the use of machinery there is a Directive 2009/104/EC.It requires that the work equipment that is provided to workers must comply with relevant Community directives.This means that when repair/changes are made on the machine it shall still fulfill the requirements of the Machinery Directive. This doesn’t have to mean that a new CE-marking is required (unless the changes are extensive).NOTE! This means that the buyer of a machine also has to make sure that a new machine fulfills the requirements in the di-rectives. If the machine does not fulfill the requirements the buyer is not allowed to use it.“Old” machinesFor machines delivered or manufactured in the EEA before 1 January 1995 the following is valid.From 2009/104/EC(b) work equipment which, if already provided to workers in the undertaking or establishment by 31 December 1992, complies with the minimum requirements laid down in Annex I no later than 4 years after that date; (c) without prejudice to point (a)(i), and by way of derogation from point (a)(ii) and point (b), spe-cific work equipment subject to the requirements of point 3 of Annex I, which, if already provided to workers in the undertaking or establishment by 5 December 1998, complies with the minimum requirements laid down in Annex I, no later than 4 years after that date. Annex l contains minimum requirements for health and safety. There can also be additional national specific require-ments for certain machines. NOTE! The point in time when the Machinery Directive was imple-mented in each Member Country varies. Therefore it is necessary to check with the national authorities in ones own country, to find out what is considered as “old” and respec-tively “new” machines.—Machinery DirectiveFrom 2006/42/EC1 § This Directive applies to the following products:a) machinery;b) interchangeable equipment;c) safety components;d) lifting accessories;e) chains, ropes and webbing;f) removable mechanical transmission devices;g) partly completed machinery.From 2009/104/ECb) work equipment which, if already provided to workers in the undertaking or establishment by 31 December 1992, complies with the minimum requirements laid down in Annex I no later than 4 years after that date;c) without prejudice to point (a)(i), and by way of derogation from point (a)(ii) and point (b), spe- cific work equipment subject to the requirements of point 3 of Annex I, which, if already provided to workers in the undertaking or establishment by 5 December 1998, complies with the minimum requirements laid down in Annex I, no later than 4 years after that date.1INTRODUCTION1– 7

Machinery that is placed on the market or put into service before 1995 in the EEA.—Risk assessment an important tool both when constructing a new machine and when assessing risks on older machines"New" machines1. Machinery that is placed on the market or put into service from 1995 in the EEA.2. All machinery that are imported to the EEA irre-spective of date of origin.Use of work equipment2009/104/ECNote! Not Annex 1 - instead use applicable directives.The Machinery Directive98/37/EC (1995 - 2009)2006/42/EC (from 2010)Possible moredirectivesEMC Directive2014/30/EUCE-marking +Declaration ofconformityLow Voltage Directive2014/35/EU"Old" machinesUse of work equipment2009/104/ECPossible national legislation on specific machines Risk assessmentA well thought-out risk assessment supports manufactur-ers/users of machines to develop production friendly safety solutions. One result of this is that the safety components will not be a hindrance. This minimizes the risk of the safety system being defeated.New machinesThe following requirement is given by the Machinery Direc-tiveFrom 2006/42/ECThe manufacturer of machinery or his authorised repre-sentative must ensure that a risk assessment is carried out in order to determine the health and safety require-ments which apply to the machinery. The machinery must then be designed and constructed taking into account the results of the risk assessment.The standard EN ISO 12100 gives guidance on the informa-tion required to allow risk assessment to be carried out.The standard does not point out a specific method to be used. It is the responsibility of the manufacturer to select a suitable method. Machines in use A risk assessment must have been carried out on all ma-chines that are in use; CE-marked as well as not CE-marked. A risk assessment must also be performed when making changes on a machine, to determine if the safety measures needs to be adapted.Documentation of risk assessmentThe risk assessment shall be documented. The risk assess-ment should take into consideration the severity of the potential injuries as well as the probability that they occur. 11– 8SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

Example on prioritizing according to the 5-step-methodProtection or warning?How is it possible to choose safety measures that are production friendly and in every way well balanced? The Machinery Directive gives an order of priority for the choice of appropriate methods to remove the risks. Here it is further developed in a five step method.Prioritize safety measures according to the 5-step-method1. Eliminate or reduce risks by design and construction2. Move the work tasks outside the risk area 3. Use guards/safety devices4. Develop safe working routines/information/education5. Use warnings as pictograms, light, sound etc.Combine the 5-step-method with production friendly thinking. This can give you e.g. –fast and easy restart of machines after a safety stop –enough space to safely program a robot –places outside the risk area to observe the production –electrically interlocked doors, instead of guards attached with screws, to be able to take the necessary measures for removing production disturbances –a safety system that is practical for all types of work tasks, even when removing production disturbancesPriority Example of hazard and safety measure taken1. Make machine safe by design and constructionHazard:Safety measure:Cuts and wounds from sharp edges and corners on machineryRound off sharp edges and corners.2. Move the work tasks out-side the risk areaHazard: Crushing of fingers from machine movements during inspection of the production inside the risk areaSafety measure: Installation of a camera.3. Use guard/safety devicesHazard: Crushing injuries because of unintended start during loading of work pieces in a mechanical pressSafety measure: Install a light curtain to detect operator and provide safe stop of the machinery.4. Safe working routines/informationHazard: Crushing injuries because the machine can tip during installation and normal use.Safety measure: Make instructions on how the machine is to be installed to avoid the risks. This can include requirements on the type of fastening, ground, screw retention etc.5. WarningHazard: Burns because of hot surfaces in reachSafety measure: Warning signsThe likelihood that the safety solution will be well made, well received and suitable for the application increases if each risk is handled according to the 5-step-method.The further away from the center of the circle, the greater responsibility for the safety is placed onto the user of the machine. If full protection is not effectively achieved in one step, one has to go to the next step and find complementary measures. What is possible is dependant on the need for accessibility, the severity of the risk, appropiate safety measures etc. 1INTRODUCTION1– 9

EN ISO 12100Safety of machinery - General principles for design - Risk assessment and risk reductionThe primary purpose of this standard is to provide designers with an overall frame-work and guidance for decisions during the development of machinery to enable them to design machines that are safe for their intended use.EN ISO 13857Safety of machinery - Safety distances to prevent hazard zones being reached by up-per and lower limbsThis standard establishes values for safety distances to prevent danger zones being reached by the upper and lower limbs. The distances apply when adequate safety can be achieved by distances alone.EN ISO 13854Safety of machinery – Minimum gaps to avoid crushing of parts of the human bodyThe object of this standard is to enable the user (e.g. standard makers, designers of machinery) to avoid hazards from crushing zones. It specifies minimum gaps relative to parts of the human body and is applicable when adequate safety can be achieved by this method.EN ISO 13850Safety of machinery – Emergency stop – Principles for designThis standard specifies design principles for emergency stop equipment for machin-ery. No account is taken of the nature of the energy source.ISO 13851Safety of machinery – Two-hand control devices – Principles for design and selectionThis standard specifies the safety requirements of a two-hand control device and its logic unit. The standard describes the main characteristics of two-hand control devices for the achievement of safety and sets out combinations of functional charac-teristics for three types. EN ISO 14120Safety of machinery – Guards – General re-quirements for the design and construction of fixed and movable guardsThis standard specifies general requirements for the design and construction of guards provided primarily to protect persons from mechanical hazards.EN ISO 13849-1Safety of machinery – Safety-related parts of control systems – Part 1: General prin-ciples for designThis standard provides safety requirements and guidance on the principles for the design of safety-related parts of control systems. For these parts it specifies categories and describes the characteristics of their safety functions. This includes programmable systems for all machinery and for related protective devices. It applies to all safety-related parts of control systems, regardless of the type of energy used, e.g. electrical, hydraulic, pneumatic, mechanical. It does not specify which safety functions and which categories shall be used in a particular case.EN ISO 13849-2Safety of machinery - Safety-related parts of control systems - Part 2: ValidationThis standard specifies the procedures and conditions to be followed for the valida-tion by analysis and testing of:• the safety functions provided, and• the category achieved of the safety-related parts of the control system in compli-ance with EN 954-1 (ISO 13849-1), using the design rationale provided by the designer.EN 62061Safety of machinery - Functional safety of safety-related electrical, electronic and pro-grammable electronic control systems The standard defines the safety requirements and guiding principles for the design of safety-related electrical/electronic/programmable parts of a control system.EN ISO 13855Safety of machinery - Positioning of safeguards with respect to the approach speeds of parts of the human bodyThis standard provides parameters based on values for hand/arm and approach speeds and the methodology to determine the minimum distances from specific sens-ing or actuating devices of protective equipment to a danger zone.EN ISO 14119Safety of machinery - Interlocking devices associated with guards - Principles for de-sign and selectionThis standard specifies principles for the design and selection — independent of the nature of the energy source — of interlocking devices associated with guards.The standard provides measures to minimize defeat of interlocking devices in a reasonably foreseeable manner.EN 60204-1Safety of machinery - Electrical equipment of machines - Part 1: General requirementsThis part of IEC 60204 provides requirements and recommendations relating to the electrical equipment of machines so as to promote:– safety of persons and property;– consistency of control response;– ease of maintenance.—Examples of regularly used EN/ISO standards11– 10SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

—Standards for safety in control systemsBuilding a protection system that works in practice and provides sufficient safety requires expertise in several areas. The design of the safety functions in the protection system in order to ensure they provide sufficient reliability is a key ingredient. As help for this there is, for example, the EN ISO 13849-1 standard. The purpose of this text is to provide an introduction to the standard and its application in conjunction with our products. Please note that outside of the European Union there are often other standards that are used in place of EN ISO 13849.Introducing the standardThe generation change for standards on safety in control systems introduced new concepts and calculations for machine builders and machine users. The EN 954-1 standard has been phased out and is replaced by EN ISO 13849-1 (PL, Performance Level) and EN 62061 (SIL, Safety Integrity Level).PL or SIL? What should I use?The standard you should use depends on the choice of tech-nology, experience and customer requirements. Choice of technology– PL (Performance Level) is a technology-neutral concept that can be used for electrical, mechanical, pneumatic and hydraulic safety solutions. – SIL (Safety Integrity Level) can, however, only be used for electrical, electronic or programmable safety solutions.ExperienceEN ISO 13849-1 uses categories from EN 954-1 for defin-ing the system structure, and therefore the step to the new calculations is not so big if you have previous experience of the categories. EN 62061 defines the structures slightly differently.Customer requirements If you or your end customer comes from an industry that is accustomed to using SIL (e.g. the process industry), require-ments can also include safety functions for machine safety being SIL rated.We notice that most of our customers prefer PL as it is tech-nology-neutral and that they can use their previous knowl-edge in the categories. In this text we show some examples of how to build safety solutions in accordance with EN ISO 13849-1 and calculate the reliability of the safety functions to be used for a particular machine. The examples in this text are simplified in order to provide an understanding of the principles. The values used in the examples can change. What is PL (Performance Level)?PL is a measure of the reliability of a safety function. PL is divided into five levels (a-e). PL e gives the best reliability and is equivalent to that required at the highest level of risk. To calculate which PL level the system achieves you need to know the following:– The system’s structure (categories B, 1-4)– The Mean Time To dangerous Failure of the component (MTTFd)– The system’s Diagnostic Coverage (DC)You will also need to:– protect the system against simultaneous failure of both channels (CCF)– protect the system from systematic errors built into the design– follow certain rules to ensure software can be developed and validated in the right wayThe five PL-levels (a-e) correspond to certain ranges of PFHD-values (probability of dangerous failure per hour). These indicate how likely it is that a dangerous failure could occur over a period of one hour. In the calculation, it is ben-eficial to use PFHD-values directly as the PL is a simplifica-tion that does not provide equally accurate results.What is the easiest way of complying with the standard?1. Use pre-calculated components.As far as it is possible, use components with pre-calculated PL and PFHD-values. You then minimise the number of calcu-lations to be performed. All ABB Jokab Safety products have pre-calculated PFHD-values.2. Use a calculation tool.With the calculation softwares FSDT or SISTEMA you avoid making calculations by hand. You also get help to structure your safety solutions and provide the necessary documenta-tion.3. Use Pluto or Vital Use the Pluto programmable safety controller or Vital safety controller. Not only is it easier to make calculations and changes in the future, but above all it is easier to ensure a higher level of safety.1INTRODUCTION1– 11

Step 1Has the risk been adequately reduced?Step 3Reduce the risk (redesign, use protection, information)Step 2Risk assessmentSTARTAre new risks generated?Is the measure dependent on the control system?Determine the system’s scope (space, usage, time, environment)Identify risk sources (all work operations during the life cycle)Estimate the risk (determine PLr with S, F and P)Evaluate the risk (is action required?)Ye sYe sNoNoYe sNoAre all safety functions executed?Determine PLrIdentify the safety functionsDesign and implement the solution for the safety functionVerify that PL ≥ PLrCalculate PLValidateHave other require ments been met?Ye sYe sNoNoENDRisk analysis11– 12SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

Risk assessment and risk minimisationAccording to the Machinery Directive, the machine builder (anyone who builds or modifies a machine) is required to perform a risk assessment for the machine design and also include an assessment of all the work operations that need to be performed. EN ISO 12100 stipulates the requirements for a risk assessment. It is this that EN ISO 13849-1 is based on, and a completed risk assessment is a prerequisite for being able to work with the standard.Step 1 – Risk assessmentA risk assessment begins with determining the scope of the machine. This includes the space that the machine and its operators need for all of its intended applications, and all operational stages throughout the machine’s life cycle.All risk sources must then be identified for all work opera-tions throughout the machine’s life cycle.A risk estimation is made for each risk source, i.e. indication of the degree of risk. According to EN ISO 13849-1 the risk is estimated using three factors: injury severity (S), frequency of exposure to the hazard (F) and the possibility you have of avoiding or limiting the injury (P). For each factor two options are given. Where the boundary between the two op-tions lies is not specified in the standard, but the following are common interpretations and our recommendations:S1 bruises, abrasions, puncture wounds and minor crushing injuriesS2 skeletal injuries, amputations and deathF1 less frequent than once per 15 min*F2 once per 15 min or exposure time exceeding 1/20 of the overall operating timeP1 slow machine movements, plenty of space, low powerP2 quick machine movements, crowded, high power* We often recommend to choose a higher value to be on the safe side, e.g. once per day.By selecting S, F and P for the risk, you will get the PLr that is necessary for the risk source.Finally, the risk assessment includes a risk evaluation where you determine if the risk needs to be reduced or if sufficient safety is ensured.Risk estimationTo calculate the performance level required (PLr).S Severity of injuryS1 slight (normally reversible injury)S2 serious (normally irreversible injury or death)F Frequency and/or exposure to hazardF1 seldom to less often and/or exposure time is shortF2 frequent to continuous and/or exposure time is longP Possibility of avoiding hazard or limiting harmP1 possible under specific conditionsP2 scarcely possibleStep 3 - Design and calculate the safety functionsTo begin with you need to identify the safety functions on the machine. (Examples of safety functions are emergency stop and monitoring of gate.)For each safety function, a PLr should be established (which has often already been made in the risk assessment). The solution for the safety function is then designed and imple-mented. Once the design is complete, you can calculate the PL the safety function achieves. Check that the calculated PL is at least as high as PLr and then validate the system as per the validation plan. The validation checks that the specification of the system is carried out correctly and that the design complies with the specification.You will also need to verify that the requirements that are not included in the calculation of the PL are satisfied, that is, ensure that the software is properly developed and validated, and that you have taken adequate steps to protect the technical solution from systematic errors.Step 2 – Reduce the riskIf you determine that risk reduction is required, you must comply with the priority in the Machinery Directive in the selection of measures: 1. Avoid the risk already at the design stage. (E.g. reduce power, avoid interference in the danger zone.)2. Use protection and/or safety devices. (E.g. fences, light grids or control devices.)3. Provide information about how the machine can be used safely. (E.g. in manuals and on signs.)If risk reduction is performed using safety devices, the control system that monitors these needs to be designed as specified in EN ISO 13849-1.abcdePLrP1P2P1P2P1P2P1P2F1F2F1F2S1S2low riskhigh risk1INTRODUCTION1– 13

PL calculation in Step 3 When you calculate the PL for a safety function, it is easi-est to split it into separate, well defined blocks (also called subsystems). It is often logical to make the breakdown according to input, logic and output (e.g. switch - safety relay - contactors), but there may be more or fewer than three blocks depending on the connection and the number of components used (an expansion relay could for example create an additional logic block) .For each block, you calculate a PL or PFHD-value. It is easiest if you obtain these values from the component manufac-turer, so you do not have to calculate yourself. The manu-facturer of switches, sensors and logic devices often have PL and PFHD-values for their components, but for mechani-cal devices (such as key switches or contactors) a PL-value cannot be supplied since it depends on how often the component will be used. You then need to calculate yourself according to EN ISO 13849-1 or use default values from the standard, if provided.To calculate PL or PFHD for a block, you need to know its category, DC and MTTFd. In addition, you need to protect the system against systematic errors and ensure that an error does not knock out both channels, and generate and vali-date any software used correctly. The following text gives a brief explanation of what to do.Safety function (SF)+ + PFHD, InputInputPL/PFHDPFHD, LogicLogicPL/PFHDPFHD, Output OutputPL/PFHDPFHD, Tot al =The relationship between categories, the DCavg, MTTFd for each channel and PL. The table also shows the PFHD-range that corresponds to each PL. PFHDPL10-4a10-5b3x10-6c10-6d10-7e10-8DC noneDC noneDC lowDC mediumDC lowDC mediumDC highCat. BCat. 1Cat. 2Cat. 2Cat. 3Cat. 3Cat. 4MTTFdlowMTTFdmediumMTTFdhigh11– 14SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

Category The structure for the component(s) in the block is assessed to determine the category (B, 1-4) it corresponds to. For category 4, for example, individual failures do not result in any loss of the safety function. In order to achieve category 4 with contactors, you need to have two channels - i.e., two contactors - that can cut the power to the machine individually. The contactors need to be monitored by connecting opening contacts to a test input on, for example a safety relay. For monitoring of this type to work, the contactors need to have positive-guided contacts.Diagnostic Coverage (DC)A simple method to determine DC is explained in Appendix E in EN ISO 13849-1. It lists various measures and what they correspond to in terms of DC. For example, DC=99 % (which corresponds to DC high) is achieved for a pair of contactors by monitoring the contactors with the logic device.Mean Time To dangerous Failure (MTTFd)The MTTFd-value should primarily come from the manufac-turer. If the manufacturer cannot provide values, they are given from tables in EN ISO 13849-1 or you have to calculate MTTFd using the B10d-value, (average number of cycles until 10% of the components have a dangerous failure). To calcu-late the MTTFd, you also need to know the average number of cycles per year that the component will execute.Calculation of the average number of cycles is as follows:dop x hop x 3600tcyclenop =B10d0,1 x nopMTTFd =wherenop = Number of cycles per yeardop = Operation days per year hop = Operation hours per daytcycle = Cycle time (seconds)Example: dop= 365 days, hop= 24 hours and tcycle= 1,800 sec-onds (2 times/hour) which gives nop= 17,520 cycles. With a B10d=2·106 this gives a MTTFd=1,141 year which corresponds to MTTFd=high. Note that when you calculate MTTFd you have to calculate ac-cording to the total number of cycles the component will be working. A typical example of this is the contactors that fre-quently work for several safety functions simultaneously. This means that you must add the number of estimated cycles per year from all the safety functions that use the contactors.When MTTFd is calculated from a B10d-value, also consider that if the MTTFd-value is less than 200 years, the component needs to be replaced after 10% of the MTTFd-value (due to the T10d-value). That is, a component with MTTFd = 160 years needs to be replaced after 16 years in order for the condi-tions for achieving PL to continue to be valid. This is because EN ISO 13849-1 is based on a “mission time” of 20 years.Common Cause Failure (CCF)In Appendix F of EN ISO 13849-1 there is a table of actions to be taken to protect against CCF, to ensure a failure does not knock out both channels.Systematic errorsAppendix G of EN ISO 13849-1 describes a range of actions that need to be taken to protect against incorporating faults into your design.PL for safety functionsPL is given in the table on the previous page. If you want to use an exact PFHD-value instead, this can be produced using a table in Appendix K in EN ISO 13849-1.Once you have produced the PL for each block, you can generate a total PL for the safety function in Table 11 of EN ISO 13849-1. This gives a rough estimate of the PL. If you have calculated PFHD for each block instead, you can get a total of PFHD for the safety function by adding together all the values of the blocks. The safety function’s total PFHD corresponds to a particular PL in Table 3 of EN ISO 13849-1.Requirements for safety-related softwareIf you use a safety PLC for implementing safety func-tions, this places requirements on how the software is developed and validated. To avoid error conditions, the software should be readable, understandable and be possible to test and maintain.A software specification must be prepared to ensure that you can check the functionality of the program. It is also important to divide the program into modules that can be tested individually. Paragraph 4.6 and Appen-dix J of EN ISO 13849-1 specify requirements for safety related software.The following are examples of requirements for soft-ware from EN ISO 13849-1: –A development life cycle must be produced with validation measures that indicate how and when the program should be validated, for example, following a change. –The specification and design must be documented. –Function tests must be performed. –Validated functional blocks must be used whenever possible. –Data and control flow are to be described using, for example, a condition diagram or software flow chart.1INTRODUCTION1– 15

Step 1 – Risk assessmentFood to be packaged is loaded into the cell manually through the rear door. A batch is prepared for the packing conveyor in the infeed hopper. The cell is reset and restart-ed. The packaging machine with conveyor belt only oper-ates when both doors are closed and when the protection system has been reset.In the risk assessment it was established that the machine is to be operated in three shifts (8 hours per shift) 365 days a year. The total access to the danger zone is estimated to be four times per hour (F2), including manual packaging and tending operational disturbances. Unexpected start-ups are not considered to cause serious injury but rather minor heal-able injuries (S1). The operator is considered not to have the possibility of avoiding injury as the machine moves quickly (P2). The number of cycles for the safety function = 365 days/year x (3x8) hours/day x 2 cycles/hour = 17,520 cycles/yearThe assessment for the safety function required for access to the machine is PLr= c (S1, F2, P2). In addition to this safety function, an emergency stop function is needed. This is also assessed as PLr=c.Determination of the PLr necessary for the safety function with interlocked door for this example.NOTE! The assessment needs to be made for each safety function.Key switch MKey5Monitors that the door is closed.Safety relay SentryMonitors safety compo-nents.Emergency stop buttonTo stop the machine in case of danger.Step 2 – Reduce the riskAs protection, an interlocked door is selected with the key switch MKey5. Stopping time is short enough for the dan-gerous movement to have ceased before the operator can access it. The emergency stop is placed within easy reach, on both sides of the cell near the doors. —Case study 1 - Safety relay SentryProtection layout for a packaging machine with low risksabcdePLrP1P2P1P2P1P2P1P2F1F2F1F2S1S2low riskhigh risk11– 16SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

PFHD, E-stop + PFHD, Sentry + PFHD, Contactors = 4.3x10-8 + 4.9x10-9 + 4.9x10-9 + 2.47x10-8 = 7.75x10-8 PL ePLr=cInputOutputSafety function 3PLr=cSafety function 1B1 MKey5 (PL c)S1 E-stop (PL e)InputLogicPFHD, MKey5 + PFHD, Sentry + PFHD, Contactors = 1.14x10-6 + 4.9x10-9 + 2.47x10-8 = 1.17x10-6 PL cK2Sentry (PL e)Q1/Q2 Contactors (PL e)Q1/Q2 Contactors (PL e)OutputThe reason for not achieving more than PL c with Safety function 1 is that only one key switch is used per door, and a key switch is mechanically a Category 1 device. For e-stop devices though, a fault exclusion for the mechanical parts is allowed according to EN ISO 13849-2 if a maximum number of operations is considered. For this solution to reach a higher PL, EN ISO 14119 and ISO/TR 24119 need to be consulted.Step 3 - Calculate the safety functionsThe output subsystem that is composed of double moni-tored contactors has been calculated at 2.47x10-8. The safety functions are represented by block diagrams.Safety functions 1 and 2 are identical. Therefore, only safety function 1 is shown.Safety functions 3 and 4 are identical. Therefore, only safety function 3 is shown.* Monitoring of contactors with K2How safe is a mechanical switch? Mechanical switches have a tendency to break if misused.Manufacturer instructions must be followed, e.g. no excessive force or dirty environment. For interlocking switches in general EN ISO 14119 must be considered. It handles e.g. the possibility to defeat a switch and require-ments on key switches. Connecting key switches in series gives a significant risk of masking errors, as stated in the technical report ISO/TR 24119, which limits the maximum achievable DC depending on the number of frequently used doors connected in series.S1 E-stopK1Sentry SSR10S2 E-stopB2 Key switchQ1ContactorB1 Key switchK2Sentry SSR10K1Q2ContactorResultResultPL cPL e*LogicK1Sentry (PL e)LogicK2Sentry (PL e)1INTRODUCTION1– 17

Step 1 – Risk assessmentThe workpieces are transported into the robot cell where the robot places them in a test cabinet. Approved workpieces leave the cell on the conveyor belt, while workpieces that fail the tests are placed on the table for manual adjustments. The work that needs to be done in the robot cell is to correct operational disturbances for the test equipment and the conveyor belt (about once/day), unloading from the manual station (about four times an hour), program adjustments (once/week) and cleaning (once/week) (F2). Unexpected start-ups of the robot are considered to cause potentially serious injury (S2). The operator is considered not to have the possibility of avoiding injury as the robot moves quickly (P2). The risk estimation gives PLr=e (S2, F2, P2) for the safety functions required for access to the machine.The standard for robot systems/cells (EN ISO 10218-2) speci-fies that safety functions shall comply with at least PL d, un-less the risk assessment determines otherwise. In this case the risk assessment gives us PLr= e.Step 2 – Reduce the riskAs protection, the door and hatch are interlocked with Eden non-contact sensors. To protect against entering the cell the wrong way, transport of materials in and out is protected with light cur-tains and provided with muting to distinguish between material and people. The emergency stop function is also a safety function that is required. The energy to all hazardous machine functions shall be re-moved by all safety functions.The solution with Vital makes it possible to implement a robot application with only one safety controller, which does not need to be configured or programmed. Vital makes it possible to connect up to 30 safety functions in a single DYNlink loop, with PL e in accordance with EN ISO 13849-1.NOTE! The assessment needs to be made for each safety function.Emergency stop button, Smile TinaTo stop the machine in case of danger.Emergency stop button INCA TinaTo stop the machine in case of danger.Light curtain, Orion Monitors the passages. Safety controller, VitalMonitors safety components in series.Non-contact sensor, EdenMonitors that the doors and hatches are closed.—Case study 2 - Safety controller VitalProtection layout for a robot cell with high risksDetermination of PLr for the safety function with interlocked door.abcdePLrP1P2P1P2P1P2P1P2F1F2F1F2S1S2low riskhigh risk11– 18SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

Step 3 - Calculate the safety functionsThe PFHD-value of the robot’s safety stop input is 5.79x10-8 (the value applies to ABB industrial robots with IRC5 control-ler). The safety functions are represented by block diagrams.These safety functions with Vital meet PL e in accordance with EN ISO 13849-1. Note that the above functions are only selected examples of the safety functions in the robot cell.PFHD, Eden + PFHD, Vital + PFHD, Robot = 4.5x10-9 + 2.74x10-8 + 5.79x10-8 = 8.98x10-8 PL ePLr=eB1Eden (PL e)InputK1Vital (PL e)LogicQ1Robot (PL e)OutputResultSafety function 1PL ePFHD, Smile Tina+ PFHD, Vital + PFHD, Robot = 4.66x10-9 + 2.74x10-8 + 5.79x10-8 = 9.0x10-8 PL eSafety function 2PLr=eS2Smile Tina (PL e)InputK1Vital (PL e)LogicQ1Robot (PL e)OutputResultPL ePFHD, Orion + PFHD, Tina 10 + PFHD, Vital + PFHD, Robot = 2.64x10-9 + 4.5x10-9 + 2.74x10-8 + 5.79x10-8 = 9.24x10-8 PL ePLr=eSafety function 3B3Orion with muting (PL e)InputK1Vital (PL e)LogicQ1Robot (PL e)OutputResultTina 10B(PL e)PL eSafety function 3 - muting of light guardsIf the logic of the muting function is included in the light guard, the PFHD-value of the light guard should include the PFHD-values for the muting components. If the logic is external (i.e. safety PLC) the muting sensors should be added as separate blocks in the safety function. B5 EdenK1 VitalS1Inca TinaS2 Smile TinaB2 EdenB4 Orion 2E with OMC1, MuteR2 and Tina 10BB3Orion 2E with OMC1, MuteR2 and Tina 10BQ1Machine stop input for robot, redundant1INTRODUCTION1– 19

—Case study 3 - Programmable safety controller PlutoProtection layout for a production cell with high risksStep 1 – Risk assessmentThe workpieces are fed into the cell through a conveyor belt and positioned by the operator in the pneumatic machining tool in station 1. The operator starts station 1 manually. The operator then places the workpiece on the conveyor belt for transfer to station 2. A light curtain prevents the operator from entering station 2 unnoticed. The robot in station 2 places the workpiece in the hydraulic press. The workpiece leaves the cell by transport out onto the conveyor.The work that needs to be done in station 2 is, e.g. to ad-dress operational disturbances in the press and the robot a few times a week (F1). Unexpected start-ups of the robot are considered to cause serious injury (S2). The operator is considered not to have the possibility of avoiding injury as the robot moves quickly (P2). The risk estimation for the safety function required for access to station 2 is PLr=e (S2, F2, P2). This estimation would still be the same for the press. For the safety function for the risks associated with the con-veyor belt, the estimation S1, F2, P1 is made giving PLr= b.Step 2 – Reduce the riskAs protection, interlocked doors are selected with the Eden non-contact sensor. Station 1 with the pneumatic machining tool is operated by a two-hand device. When the two-hand device is released, the dangerous movement will be stopped safely. Station 2 can be in automatic mode, when a light curtain (Orion) and a non-contact sensor at door 4 (Eden) protects the entry. If the door is opened or the light curtain is interrupted, energy to the hazardous functions in station 2 is removed. By opening doors 2 and 3 (also monitored by Eden sensors) the conveyor belt and the pneumatic machin-ing tool will stop safely. Manual reset must always be done after actuation of any safety device.When the protection system requires a number of safety devices and that multiple machines must be stopped, Pluto programmable safety controller is the most effective solu-tion. If the protection system also has to work by zones and in different modes of operation, this is another good reason to use Pluto. With Pluto, PL e can be achieved regardless of the number of connected safety devices.PLr= d for the robot and hydraulic press. PLr=b for the conveyor belt.Programmable safety controller Pluto Monitors safety components.Station 2Station 1Door 4Door 3Door 2Door 1RobotConveyor beltabcdePLrP1P2P1P2P1P2P1P2F1F2F1F2S1S2low riskhigh riskabcdePLrP1P2P1P2P1P2P1P2F1F2F1F2S1S2low riskhigh risk11– 20SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

Step 3 - Calculate the safety functions for the robot cellThe PFHD-value for the robot’s safety stop input is 5.79x10-8 (the value applies to ABB industrial robots with IRC5 control-ler).Only safety functions to help remove energy to the industrial robot are shown below. This is only a subset of the safety functions. When energy is removed to multiple machines in a cell, the safety functions can be defined in different ways depending on the risk assessment. The safety functions are represented by block diagrams.These safety functions with Pluto meet PL e in accordance with EN ISO 13849-1. Note that the above functions are only selected examples of the safety functions in the robot cell.PFHD, Eden + PFHD, Pluto + PFHD, Robot = 4.5x10-9 + 2x10-9 + 5.79x10-8 = 6.44x10-8 PL ePLr=dSafety function 1B1 Eden (PL e)InputK1Pluto, relay outputs (PL e)LogicQ1Robot (PL e)OutputPL eResultPFHD, Smile Tina + PFHD, Pluto+ PFHD, Robot = 4.66x10-9 + 2x10-9 + 5.79x10-8= 6.46x10-8 PL ePLr=dS2 Smile Tina (PL e)InputQ1Robot (PL e)OutputPL eResultSafety function 2K1 Pluto, relay outputs (PL e)LogicPFHD, Orion + PFHD, Tina 10 + PFHD, Pluto + PFHD, Robot = 2.5x10-9 + 4.5x10-9 + 2x10-9 + 5.79x10-8 = 6.69x10-8 PL ePLr=dB5 Orion (PL e)InputQ1Robot (PL e)OutputPL eResultK1Pluto, relay outputs (PL e)LogicTina 10A(PL e)Safety function 3S1Two-hand device, SafeballS2–S4Emergency stop, Smile TinaB1–B3Non-contact sen-sor EdenB4–B5Non-contact sensor Eden/Light curtain Orion with Tina 10AQ3Pneumatic machining toolQ2Hydraulic pressQ1 Machine stop input for robot, redundant1INTRODUCTION1– 21

SF1SF3SF2K1Logic unitS1E-stop buttonF1Light curtainQ1MachineB1Interlocked switchS1E-stop buttonQ3Machine 3B1Interlocked switchF1Light curtainQ1Machine 1Q2Machine 2K1Logic unitMultiple safety functions for a machine Multiple safety devices are often used on a machine in order to provide satisfactory and practical protection for the op-erators. In the following example, a machine is protected by three safety devices connected to a logic device. The follow-ing figure illustrates this interconnection schematically.Calculating that you have achieved the PLr that is required is not difficult, especially if you use “pre-calculated” safety devices and logic units. But which parts should be included in each safety function?This must be resolved before you start the calculations. To summarise in simple terms you can say that each safety device should be a part of the safety function for each machine that is affected by the safety device in question. Three safety devices that all remove the energy to three machines in a cell is therefore equal to nine safety functions. In the section that follows, we explain the background.Three safety functions (SF) are defined for the machine and are calculated as:SF1: PFHD, F1 + PFHD, K1 + PFHD, Q1= PFHD, SF1SF2: PFHD, B1 + PFHD, K1 + PFHD, Q1= PFHD, SF2SF3: PFHD, S1 + PFHD, K1 + PFHD, Q1= PFHD, SF3Multiple safety functions for multiple machines in a cell It is quite common for several machines in a single cell/zone to be protected by multiple safety devices. The following figure illustrates the interconnection schematically for an example. Each of the machines Q1 – Q3 is shut down separately and independently by K1. If the operator enters the cell, he is exposed in this case to the same type of risk from all three machines. The power to all three machines must be cut e.g. when the operator enters the cell through the door interlocked by B1.—What defines a safety function?11– 22SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

Conclusions –Use the practical approach for multiple machines. –Use safety devices/logic units with high reliability (low PFHD) to make it easy to achieve the PLr required. –With Vital or Pluto, it is easier to achieve the PLr re-quired.Sources:http://www.dguv.de/medien/ifa/en/pra/en13849/safe-ty_functions.pdfTheoretical approach for multiple machinesThe theoretical approach to calculate the safety function is as follows:Q3Machine 3B1 Interlocked switchQ1Machine 1Q2Machine 2K1Logic unitFor the full safety function to be performed you require all the components to be working. Note that if B1 or K1 has a dangerous malfunction, the entire safety function is dis-abled. However, if for example machine Q1 has a dangerous malfunction, and is not shut down, machines Q2 and Q3 will still be shut down. One disadvantage in considering the safe-ty function in this way is that you may have trouble achieving the PLr required. But if you achieve the PLr required, you can use the theoretical approach.Practical approach for multiple machinesA more practical approach is to divide the safety func-tion into three parts, one for each of the three machines.B1Interlocked switchQ2Machine 2K1Logic unitB1Interlocked switchQ3Machine 3K1Logic unitB1Interlocked switchQ1Machine 1K1Logic unitThis is an approach that can provide a more accurate way of looking at the safety functions, especially where a different PLr is required for the safety functions above. If machine Q1 is a robot and machine Q2 is a conveyor which is de-signed to have negligible risks, the different PLr required to protect against risks from Q1 and Q2 will also be different. This practical approach is therefore the one recommended. The interpretation is based on information provided by IFA (Institut für Arbeitsschutz der Deutschen Gesetzlichen Unfallversicherung). For more information on this and other issues, see Sources.Practical approach If you use the practical approach the safety functions are as follows:Robot:PFHD, B1 + PFHD, K1 + PFHD, Q1 = 4.5x10-9 + 2•10-9 + 5.79x10-8 = 6.44x10-8 PL eHydraulic press:PFHD, B1 + PFHD, K1 + PFHD, Q2 = 4.5x10-9 + 2•10-9 + 8x10-8 = 8.65x10-8 PL ePneumatic machining tool:PFHD, B1 + PFHD, K1 + PFHD, Q3 = 4.5x10-9 + 2x10-9 + 2x10-7 = 2.07x10-7 PL dThis is to be done in a similar way with other safety functions for the cell. For each safety device, you define the machines it affects, and establish the various safety functions according to this. Theoretical approach What would the result be using the theoretical approach? Would the safety function achieve PL e?All machines:PFHD, B1 + PFHD, K1 + PFHD, Q1 + PFHD, Q2 + PFHD, Q3 = 4.5x10-9 + 2x10-9 + 5.79x10-8 + 8x10-8 + 2x10-7 = 3.44x10-7 PL dIn this case, the safety function would not achieve a total PL e, which was required for the risks associated with the robot and hydraulic press. Example of safety functions for multiple machines in a cell For a cell with three machines (one robot, one hydraulic press and one pneumatic machining tool) a risk assessment is made resulting in different PLr for the individual machines. The robot and the hydraulic press requires PLr = e, while the pneumatic machining tool requires PLr = d.One of the safety functions is that a non-contact sensor (Eden) supervised by a safety PLC (Pluto) shall disconnect the energy to all three machines in the hazard zone: –Eden B1 (PFHD, B1 = 4.5x10-9) –Pluto K1 (PFHD, K1 = 2x10-9) –Robot Q1 (PFHD, Q1 = 5.79x10-8) –Hydraulic press Q2 (PFHD, Q2 = 8x10-8) –Pneumatic machining tool Q3 (PFHD, Q3 = 2x10-7).Please note that the examples on these pages are simplified in order to ex-plain the principles. Values of products can also change.1INTRODUCTION1– 23

—FSDT and SISTEMATools for determining performance level (PL) Tools to simplify the process of safety function designFSDT is an ABB software for determining PL and SIL of safety functions and generating technical documentation. The tool helps simplifying the process of safety function design, verification and documentation. It supports the compliance of the requirements of both EN ISO 13849-1 and IEC 62061 as well as the European Machinery Directive. FSDT is freeware and can be downloaded from the ABB website.Another commonly used software tool for the calculation of PL according to EN ISO 13849-1 is SISTEMA, developed by IFA (The Institute for Occupational Safety and Health) in Ger-many. With SISTEMA it is possible to “build” safety functions, verify them and generate the technical documentation required. The tool is freeware and can be downloaded from the IFA website.To simplify the use of FSDT and SISTEMA with our products we have created a library con-taining all of our safety products. 2TLC172300D020111– 24SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY

Safety Integrity Level, SILProbability of dangerous Failure per Hour (PFHD)3≥10-8 to <10-72≥10-7 to <10-61≥10-6 to <10-5There is a method in IEC/EN 62061 for assigning the Safety Integrity Level.Severity (Se)Class (Cl)3-45-78-1011-1314-154SIL2SIL2SIL2SIL3SIL33(OM)SIL1SIL2SIL32(OM)SIL1SIL21(OM)SIL1Cl=Fr+Pr+Av OM=Other MeasuresThe severity of injury that can occur is divided into four levels. Class is the addition of the values of frequency (Fr, stated as a value between 1 and 5, where 5 represents the highest frequency), probability that a dangerous event will occur (Pr, stated as a value between 1 and 5, where 5 repre-sents the highest proability) and the possibility of avoiding or limiting injury (Av, stated as a value of 1, 3 or 5, where 5 represents the least chance of avoiding or limiting an injury). The safety function that is to be designed must at least fulfill the SIL that has been assigned to it in the risk assess-ment. The safety function consists of a number of sub-elements. Example: a door is interlocked by a non-contact sensor which is in turn monitored by a Pluto safety PLC, with outputs that break the power to two supervised contac-tors. The sensor is sub-element 1, Pluto is sub-element 2 and the two supervised contactors are sub-element 3. If in the assessment it has been established that SIL2 shall be used, every individual sub-element in the safety function must fulfill the SIL2 requirements. And the safety function must in its entirety fulfill the SIL2 requirements.If the SIL requirements are not fulfilled in any of the sub-elements or by the safety function in its entirety, a re-design must be made. FinallyThis is just a brief introduction to the EN ISO 13849-1 and IEC/EN 62061 standards. You are welcome to contact us for more information and we are happy to guide you in how to apply the standards to our products.The information given in this document is not intended to replace the standards - we strongly encourage you to pur-chase the standards if you are working with machine safety.Definition of protective safety in accordance with IEC/EN 62061"Function of a machine whose failure can result in an immediate increase of the risk(s)"If a safety function is designed in accordance with IEC/EN 62061, the level of reliability is expressed as the Safety Integrity Level, SIL. There are a total of 4 levels, but in the IEC/EN 62061 standard SIL 3 is the highest level. SIL is similar to PL (performance level) and uses the same PFHD (probability of dangerous failure per hour) to express the reliability of components and systems.—Applying IEC/EN 62061INTRODUCTION1– 251

SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY2

—Safety controllers2– 2 Introduction and overview 2– 6 Programmable safety controller Pluto2– 16 Safety controller Vital2– 22 Safety relay Sentry SAFETY CONTROLLERS2– 12

—Introduction and overviewSelection guideThe safety controllers from ABB can monitor anything from a single safety function to complete manufacturing lines. PlutoVitalSentryImageTy p eProgrammable safety controllerSafety controllerSafety relayDescriptionA cost-effective, powerful and compact programmable safety controller for all types of safety applications.A configurable safety controller that can monitor all safety devices on smaller machines.Powerful and easy-to-install safety relays suitable for all common types of safety devices.Application(s)Monitoring of multiple safety de-vices and several safety functions, as well as control of machines and/or processes. Many I/Os and pro-grammable logic.Monitoring multiple safety devices with all the advantages of the DYN-link system.Monitoring safety devices with one safety function, as well as expan-sion of safety outputs, with or without time delay.Compatible safety devicesAll types of conventional safety devices and DYNlink devicesDYNlink devicesAll types of conventional safety devicesAdvantages- Easy-to-use while still allowing advanced programming- Free software- Easy system modification- Gateway communication with all main fieldbuses- Monitor up to 30 sensors in series maintaining Cat. 4/PL e- No programming- Easy and fast to install with push-in terminals- Universal models for all common applications- Extensive status information- Advanced timer functions- Multireset of up to 10 safety relays2– 2SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY2

Conventional safety devicesBy conventional safety devices, we mean safety devices with one or two channels with contacts (e.g. key switches and emergency stop buttons), devices with OSSD outputs (e.g. light guards and Eden OSSD), safety devices with solid state outputs (e.g. safety magnetic sensors) and pressure sensitive devices (e.g. safety mats, safety edges and bumpers).A safety controller compatible with conventional safety devices can be used with most safety devices on the market, independently of the brand.The DYNlink solutionThe DYNlink solution is a unique ABB Jokab Safety feature allowing to connect safety de-vices in series and still reach category 4/PL e/SIL 3 with only one channel (instead of two with conventional safety devices). This saves cabling and hardware.For a small machine, the Vital safety controller can be a very cost effective solution since up to 30 DYNlink devices can be connected to one Vital and still reach category 4/PL e/SIL 3. With conventional safety devices this would require one safety relay per safety device.When Pluto programmable safety controller is used, only one safety input is necessary for each DYNlink circuit instead of two inputs for a traditional safety device, which means that less I/Os are necessary.Tina adapters allow to use conventional safety devices in a DYNlink solution and transform between DYNlink signals and conventional safety signals, while maintaining the highest level of safety. This means that most conventional safety devices can be used in a DYNlink solu-tion when used together with a suitable Tina adapter.—OverviewSelection orientation Programmable logicQuite often, there is a need for logic between the different safety functions. For instance: IF (“door A” AND “door B” are open) OR (“door C” is open) THEN “Action 1”. A logic like this can be hardwired without using programmable safety controllers, but the cabling becomes much more complicated, modifications are time consuming, errors happen more often and are difficult to find.With a programmable safety controller, the safety devices are simply connected to the safe inputs of the controller and the logic is made in the program of the safety controller. The logic is then easy to modify without changing anything in the cabling. The Pluto Manager programming software allows to test the logic and see on the screen if there are any prob-lems, which means much faster troubleshooting. Pluto also offers many functions that enables it to do much more than supervising safety functions. It can e.g. control the complete manufacturing process of a smaller machine, thus saving the cost of a standard (non-safety) PLC. SAFETY CONTROLLERS2– 32

—Introduction and overviewStandardsStandardsSome of the more important safety standards to follow when designing safety solutions are:EN ISO 12100 - Risk assessmentEN ISO 13849 - Performance LevelEN ISO 62061 - SILISO/TR 23849 - Guidance on the use of the PL and SIL standardsEN 60204 - Electrical equipment2– 4SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY2

SAFETY CONTROLLERS2– 52

Pluto is a cost effective, powerful and compact programmable safety controller used in a variety of applications: in large and small systems for process and functional safety.Pluto can control most types of safety devices on the market, as well as ABB Jokab Safety DYNlink safety devices, analog sensors, encoders, con-tactors, valves and many more. Programming is done easily in the complimentary software, Pluto Manager.The models with safety bus communication sim-plify the design of safety systems, thanks to our All-Master concept. A wide range of gateways al-lows communication with other networks and also remote monitoring of a Pluto system.Continuous operationProgramming software free of chargePluto Manager is an easy to use PC based programming software provided free of charge.Easy programmingReady-made TÜV approved function blocks for safety functions make it easy to reach PL e/SIL3. Ladder logic and text programming allow the de-sign of more advanced functions and the control of complete machines.Communication with external net-worksPluto gateways provide a two-way communication between the Pluto safety bus and other field buses.Optimum interfaceEasy modificationEasy and quick replacement of units without any configuration.Flexible monitoringOnline monitoring from any Pluto in the system and remote monitoring and control with an Ethernet gateway. —Programmable safety controllerPlutoGreat flexibilityUp to 32 Pluto units can exchangedata on the same safety bus, and theunique All-Master system allows simplescaling, splitting and modification.Powerful yet compactUnexpected features for its size, likereal programming and speed monitor-ing, enables replacement of more com-plex PLC systems in some applications.More sensors and less cablingThe DYNlink solution allows seriesconnection of up to 10 safetydevices on each input.StatusBus and light button featurealso reduces cabling to a minimum.Speed up installation2-6SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY2

DYNlink solutionThe DYNlink circuit is a unique solution that allows up to 10 DYNlink devices to be connected in series to a Pluto input while still reaching up to Cat. 4/PL e/SIL3. This saves inputs and cabling, since to reach the same level with standard two-channel safety devices, two inputs are necessary and series connection is not possible.The DYNlink solution checks the signal 200 times/second and a fault such as a short circuit will be detected before any safety device is used.Examples of DYNlink devices are Eden and Smile Tina. Most two-channel safety devices can be connected to the DYNlink solution using Tina adapters.StatusBus functionalityThe StatusBus functionality is available with some DYNlink devices and allows to collect the status of each individual safety device, even when connected in series. A single input on Pluto can collect the status of up to 30 safety devices. The devices are connected using standard cable and M12-5 connectors. No specific bus cable or extra communication module is necessary. All Pluto models offer the StatusBus functionality.—FeaturesPlutoSafety bus with All-Master functionThe unique All-Master system allows simple scaling, split-ting and modification of the safety system.In a traditional safety PLC network, there is one Master and additional Slave units. But for Plutos connected to a safety bus, all units are Masters and make their own decisions, while still having the possibility to listen to what is hap-pening to the other Plutos on the safety bus. This enables great flexibility when it comes to modification of the safety system. It also enables very simple replacement of a broken Pluto, since all Plutos have a copy of the application soft-ware of all other Plutos on the safety bus stored locally. If the replacement Pluto is given the same ID as the broken Pluto (using IDFIX), the software is downloaded from the safety bus with a simple button on the front of Pluto.Up to 32 Pluto units can be connected to the Pluto safety bus. The Pluto S20 and S46 are stand-alone models and can-not be connected to the Pluto safety bus. All other models have bus functionality. The Safety bus functionality is neces-sary in order to use a Pluto gateway.I/OsFailsafe inputs (I) are used to connect the safety devices tobe monitored. Some of them can be used as analog inputsand counter inputs. The choice is made in the Pluto programwhen the I/Os are configured. Depending on the model, theanalog inputs can be low resolution 0-27 V or high resolution0-10 V/4-20 mA. The fast counter inputs can handle frequen-cies up to 14 kHz.Failsafe inputs/non-failsafe outputs (IQ) are terminals thatcan be used as failsafe inputs or communication outputs(non-failsafe). The choice is made in the Pluto program whenthe I/Os are configured. A specific configuration is “light button” which means that both the contact and the LED in-dicator of an illuminated push-button are connected to only one IQ, thus saving one I/O. Failsafe outputs (Q) are individually safe and independentlyprogrammable outputs. There are both relay and transistoroutputs. The transistor outputs deliver a negative voltage(-24 VDC) that facilitates the detection of a short circuit with other voltage potentials and increases safety. The tran-sistor outputs are primarily intended for electromechanical components such as contactors and valves.StatusBus logotypeSAFETY CONTROLLERS2-72

Pluto ManagerPluto Manager is the programming software for Pluto, downloaded free of charge from our website http://new.abb.com/low-voltage/products/safety-products/program-mable-safety-controllers/plutoAn update function in Pluto Manager helps you to always have the latest version installed as long as you have an Inter-net connection. Pluto Manager is a user friendly PC software that allows a simple configuration of the Pluto I/Os and programming in ladder logic and with TÜV approved func-tion blocks.Examples of what the available function blocks can handle: - Two-channel safety devices, with or without Reset and Monitoring. - Single channel functions with Reset. - Muting functions - Encoders and counters - Communication with Gateways and StatusBus Examples of ladder logic functions provided: - Boolean instructions, Edge/inverted edge detection, Latch function, Toggle - Timers - Addition, Subtraction, Multiplication, Division - Remanent memories - Registers: 16 and 32 bit - Sequence programming - Option handling - Online monitoringIn Pluto Manager there is a unique Option handling function suitable for series production of machines with different customer options. All versions of a machine type can have the same PLC program. To handle the different customer options, check boxes are used to set memories that activate the different functions of the code.Current monitoringPluto A20 has a special current monitoring function. The function is mainly used to check if the connected muting lamps are working.—FeaturesPlutoRemote monitoring and controlRemote monitoring allows the connection to a remote Plutosystem via the Internet and an Ethernet gateway. Pluto Man-ager is used for the monitoring.This function can be used for:- Support of local maintenance personnel during trouble-shooting- Regular monitoring of the status of the machine or process- Follow-up of operational data like number of cycles/day orruntime. Pluto Manager also offers remote control of a Pluto system using the Internet and an Ethernet gateway.With the remote control function it is possible to:- Download a program from PC to the remote Pluto- Configure addressing of AS-i and StatusBus slaves, write IDFIX codeThe security of the remote control function is guaranteed by use of the K-button on Pluto. A change in a remote Pluto sys-tem cannot be made without a person at the remote Pluto confirming the action by pressing the K-button. Configuration of the gateway itself, e.g. switching remote control on/off, can only be made via the programming port on the gateway and not via the Ethernet port.2-8SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY2

—AccessoriesPlutoOperator panelsAn operator panel can be connected to the programming port of Pluto with a specific cable and communicate with Pluto in MODBUS ASCII. We recommend the ABB CP600 series operator panels that offer the appropriate communi-cation driver.An operator panel can also communicate with Pluto via a GATE-MT gateway.Pluto gatewaysPluto gateways provide two-way communication between the Pluto safety bus, i.e. all the Pluto units connected to it, and other field buses. Several models are available for the most common field buses.Ready-made function blocks in Pluto Manager facilitate the communication. A gateway can be located anywhere on the Pluto safety bus.Pluto safe encodersRotary absolute encoders can be used for safe position determination. Our safe encoders are intended to be connected to the Pluto safety bus. They are available in single and multi-turn ver-sions, with shaft or hollow shaft. Up to 16 absolute encoders can be connected to a Pluto safety bus. In Pluto Manager, specific function blocks make it easy to read and evaluate the values of two encoders forming a PL e/SIL3 solution. Apart from position, the speed values are available which means that also zero speed and overspeed can be moni-tored.Examples of applications are gantry robots, industrial ro-bots, and also eccentric shaft presses, where the encoders can replace existing cam mechanisms.SAFETY CONTROLLERS2-92

2TLC010035V0201Pluto S20 v2—Ordering informationPlutoSafety busFailsafe outputs a)Failsafe inputs (max) b)Analog inputs (max) b)Fast counter inputs(max) b)StatusBus inputs (max) b) Non failsafe outputs(max) b)Width mmTy p e Order codeNo4161 c)-4845Pluto S202TLA020070R47006403 c)-41690Pluto S462TLA020070R1800Ye s-221 c)-4845Pluto B22 e)2TLA020070R480024--2245Pluto O2 f)2TLA020070R85004161 c)-4845Pluto A20 g)2TLA020070R4500Pluto B202TLA020070R46004 d) + 1 c)-4845Pluto D202TLA020070R64006403 c)-41690Pluto B462TLA020070R1700398 d)441590Pluto D452TLA020070R6600a)Failsafe outputs2 failsafe outputs: - 2 independent individually safe potential free relay outputs (Q0 and Q1) with 3 contacts each4 failsafe outputs: - 2 independent individually safe potential free relay outputs (Q0 and Q1) - 2 independent individually safe transistor outputs (-24 VDC) (Q2 and Q3)6 failsafe outputs: - 2 independent individually safe potential free relay outputs (Q0 and Q1) - 2 independent individually safe potential free relay outputs with common supply (Q4 and Q5) - 2 independent individually safe transistor outputs (-24 VDC) (Q2 and Q3)b) -The number of failsafe inputs available decreases with the number of used non-failsafe outputs, analog inputs, f ast counter inputs and StatusBus inputs. -The number of analogue inputs available decreases with the number of used fast counter inputs. -The number of non-failsafe outputs available decreases with the number of StatusBus inputs used. Check the Pluto hardware manual for more information.c)0-27 V analog inputsd)0-10 V/4-20 mA (high resolution) analog inputse)Expansion model with failsafe inputs and no failsafe outputs.f)Expansion model with 2 failsafe outputs with 3 contacts each. Also possible to use as stand-alone unit.g)Model with current monitoring Pluto A20 v22TLC010008V0201Pluto D452TLC010029V0201Failsafe inputs / Outputs (not failsafe) / Dynamic outputsIQ10IQ11supplyPower+24VIQ12IQ13Identifier IDFIXIQ15IQ14IQ16I30BInputs, individual failsafeQ0IQ17I31I32I33I34I35I36Q2AI37Pluto B46, S46Pluto busI45I40I41I42I43I44I46I47Inputs, individual failsafeI0I1I2I3I6I5I4I7IQ21IQ20IQ25IQ24IQ23IQ22IQ27IQ26BAAQ1BAQ4BQ5ABQ3BA0V0VIDCHCL1)AIAIAISR46SR45SR414L1L0LSafety outputsDigital/AnalogueInputs, individual failsafeCLI0CHIDPluto O2IQ10Q1BIQ1133A1314+24V 0VCSh232434B333413142324AQ0I1250VAC, 5A24V, 1.5A24V, 1.5A250VAC, 5APower supplySafety Output ModuleSafe inputsNon-safe outpDynamic outpSafe inputsNon-safe outpDynamic outp—Pluto ordering tablePluto is available in different models depending on the needs of your application. Optional features includes bus communication, high resolution analog inputs and current monitoring. 2-10SAFETY PRODUCTS CATALOG ABB JOKAB SAFETY2

IDFIX-PROG 10k2TLC172613F0201IDFIX-PROG 2k52TLC172611F0201—Ordering informationPluto accessoriesDescriptionTy p e Order codePre-programmed unique identification number.IDFIX-R 2TLA020070R2000 Programmable identification number, i.e. the user can choose identification number.IDFIX-RW 2TLA020070R2100 Programmable identification number and storage of AS-i safety codes. IDFIX-DATA 2TLA020070R2300 Storage of the Pluto program, 2.5 Kbyte. Especially useful for stand-alone Pluto.IDFIX-PROG 2k5 2TLA020070R2400 Storage of the Pluto program, 10 Kbyte. Especially useful for stand-alone Pluto.IDFIX-PROG 10k 2TLA020070R2600 DescriptionTy p e Order codePluto programming and on-line monitoring cable. For a PC serial port, 9-pole D-sub connector. Pluto cable serial2TLA020070R5600 Pluto programming and on-line monitoring cable. For a PC USB port.Pluto cable USB2TLA020070R5800 Cable for connecting a HMI-panel to the Pluto programming port. Connector on HMI-side: 15-pole D-sub. On Pluto side: 90 degrees angled Modbus contact.Pluto cable HMI2TLA020070R5700 Cable for connecting HMI-panel ABB CP400 to Pluto programming port. Connector on HMI-side: 9-pole D-sub.Pluto cable CP4002TLA020070R6700 Cable for connecting HMI-panel ABB CP600 to Pluto programming port. Connector on HMI-side: 9-pole D-sub.Pluto cable CP6002TLA020070R6900 Bus cable for Pluto safety bus, 2 x 0.75 mm2. Ordered by meter, cut to size. Minimum order length 10 m.PCABLE-0002TLA020070R6800Bus cable for Pluto safety bus, 2 x 0.75 mm2. 50-meter ring.PCABLE-0502TLA020070R6805Bus cable for Pluto safety bus, 2 x 0.75 mm2. 100-meter ring.PCABLE-1002TLA020070R6810Bus cable for Pluto safety bus, 2 x 0.75 mm2. 500-meter drum.PCABLE-5002TLA020070R6850Bus cable for Pluto safety bus, 2 x 0.75 mm2. Halogen free. Ordered by meter, cut to size. Minimum order length 10 m.PCABLE-000-HF2TLA020070R8600Bus cable for Pluto safety bus, 2 x 0.75 mm2. Halogen free. 50-meter ring.PCABLE-050-HF2TLA020070R8605Bus cable for Pluto safety bus, 2 x 0.75 mm2. Halogen free. 100-meter ring.PCABLE-100-HF2TLA020070R8610Bus cable for Pluto safety bus, 2 x 0.75 mm2. Halogen free. 500-meter drum.PCABLE-500-HF2TLA020070R8650DescriptionTy p e Order codeSet of function blocks for mechanical presses.Pluto press block2TLA020070R4100Smile reset button for light button function with M12-5 connector.Smile 11 RB2TLA030053R0100Handheld terminal for StatusBus. Used for e.g. addressing and test. Connection to PC via USB-micro cable FIXA2TLA020072R2000Terminating resistor for Pluto safety bus. Necessary for each stand-alone Pluto and on the Pluto units at each end of the Pluto safety bus. Should be removed from the other Pluto units.R120 Resistor2TLA020070R2200 DescriptionTy p e Order codeContact block for safety relays and Pluto. 7 poles. Grey.Contact block 7 grey2TLA081200R1500IDFIX-R2TLC172609F0201IDFIX-RW2TLC172765F0201IDFIX-DATA2TLC172607F0201R120 Resistor2TLC172624F0201FIXA—Pluto cables and connection accessories—IDFIX identifiersIDFIX is an identification circuit that is connected to Pluto. It must be used: • when several Pluto are connected to the Pluto Safety bus (IDFIX-R or IDFIX-RW) • to get the possibility to replace a stand-alone Pluto with a new one without the need of a PC (IDFIX-PROG stores the Pluto program)—Other accessories—Pluto spare parts (included when ordering a Pluto)SAFETY CONTROLLERS2-112